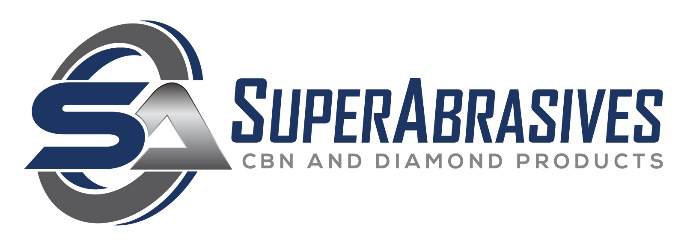

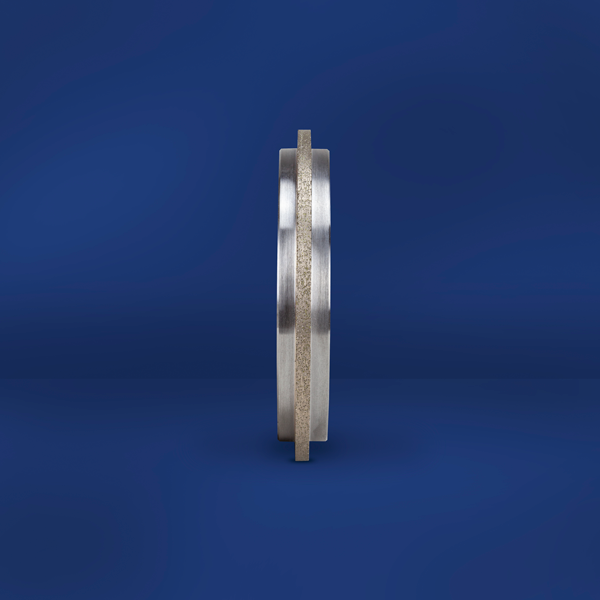

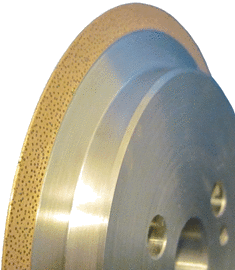

We have a line Metal Bond Rotary Diamond Dressing Wheels that are designed specifically for dressing our vitrified CBN and diamond wheels. These products are available in most industry standard shapes and sizes and provide a cost effective solution to your dressing needs.

Electroplated

Some characteristics of our dressing wheels include a hard metal bond matrix that provides excellent life while still providing superior conditioning of the grinding wheel. This product line is ideal for truing the OD and face of vitrified wheels using a traverse application but is not recommended for any type of profile dressing operation or for dressing conventional abrasive wheels.

Our Relap and Resize Service provides an excellent benefit that can extend the dresser life multiple times over by reconditioning the matrix – no more throwing away the dresser after the initial us. Now you can extend the life of the dresser to get the most return on your investment and reduce the lead time when compared to ordering a brand new tool.

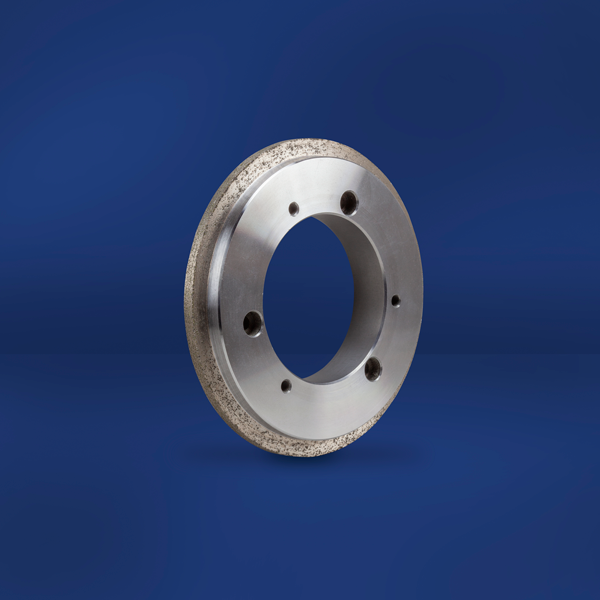

We also have numerous single point type dressing tools and nibs that are ideal for multiple bond types and dressing applications. These tools com in standard industry shapes and sizes and like our metal bond dressing wheels are engineered specifically to dress our vitrified CBN and diamond wheels. BUT the added benefit is that they also dress most grinding wheel bond types used in the field today.

For more detailed information on any of the products and services mentioned above talk with your sales representative, call us directly at (248) 348-7670, or email us at sales@superabrasives.com.