When ordering new custom designed products from us, two options are available to you – our Design Service or Your Provided Designs. Our application engineers are familiar with the requirements associated with the use and manufacturing of plated wheel cores and will work with you to get the proper design. But if you prefer to do all of the design work yourself that’s not a problem for us either and we’ll work with your designs and your staff to confirm the final design.

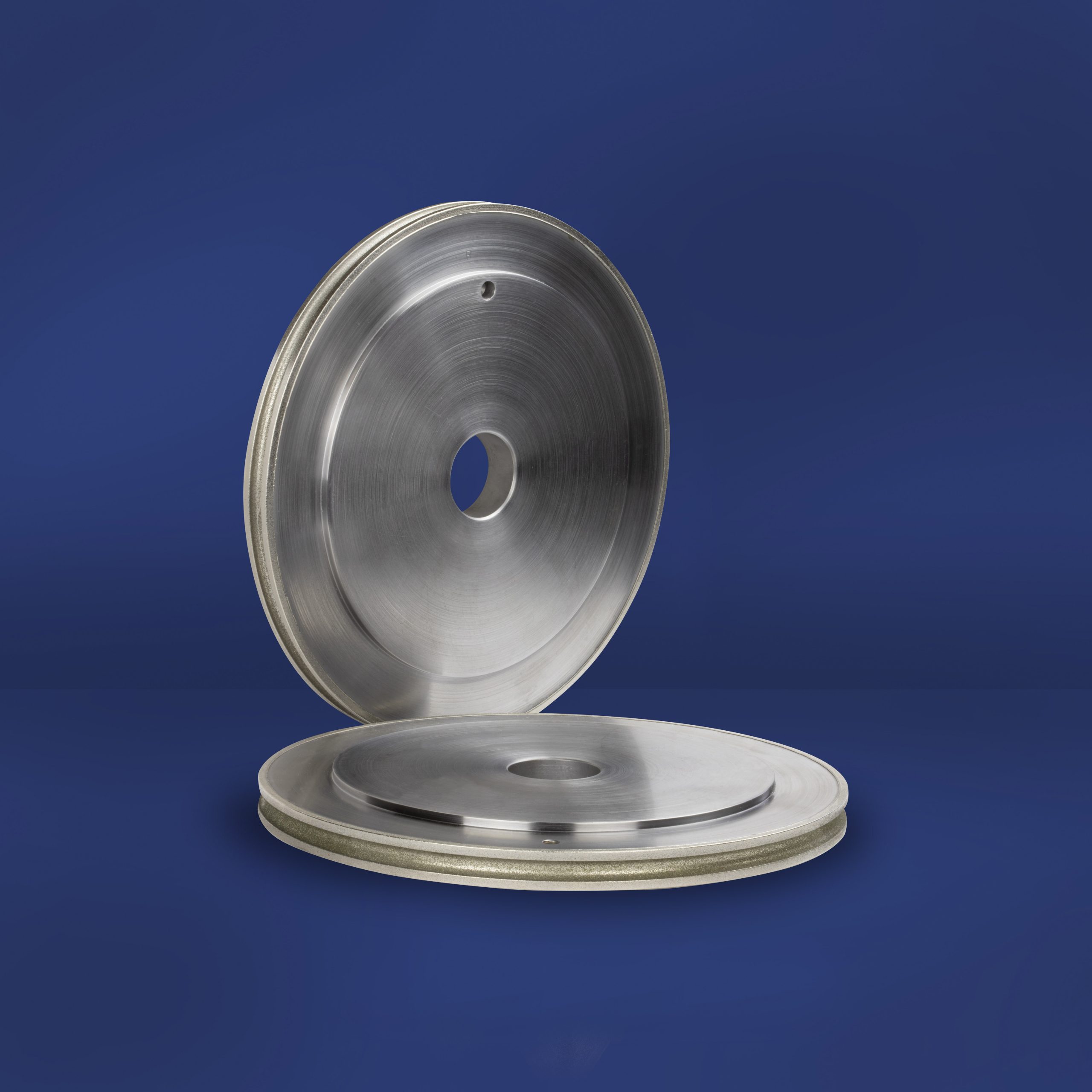

Going hand in hand with our Design Service, our machining service provides our customers with a worry free solution for core manufacturing. Because we know how critical form tolerances are on the cores themselves, our machining and grinding services are a worry-free solution for any product requirement. Ask us how this service can benefit you.

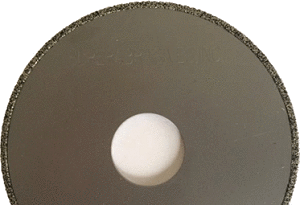

Our Diamond and CBN Electroplated Products are available ranging from small I.D. mandrels to large face style wheels up to 24″ in diameter. And our strip and replate service is proven to provide fast turn- around times when the need to keep production running becomes the most critical part of your project.

For more detailed information on any of the products and services mentioned above talk with your sales representative, call us directly at (248) 348-7670, or email us at sales@superabrasives.com.

TIGHT FORM TOLERANCES | DESIGN SERVICE | STRIP & REPLATE SERVICE