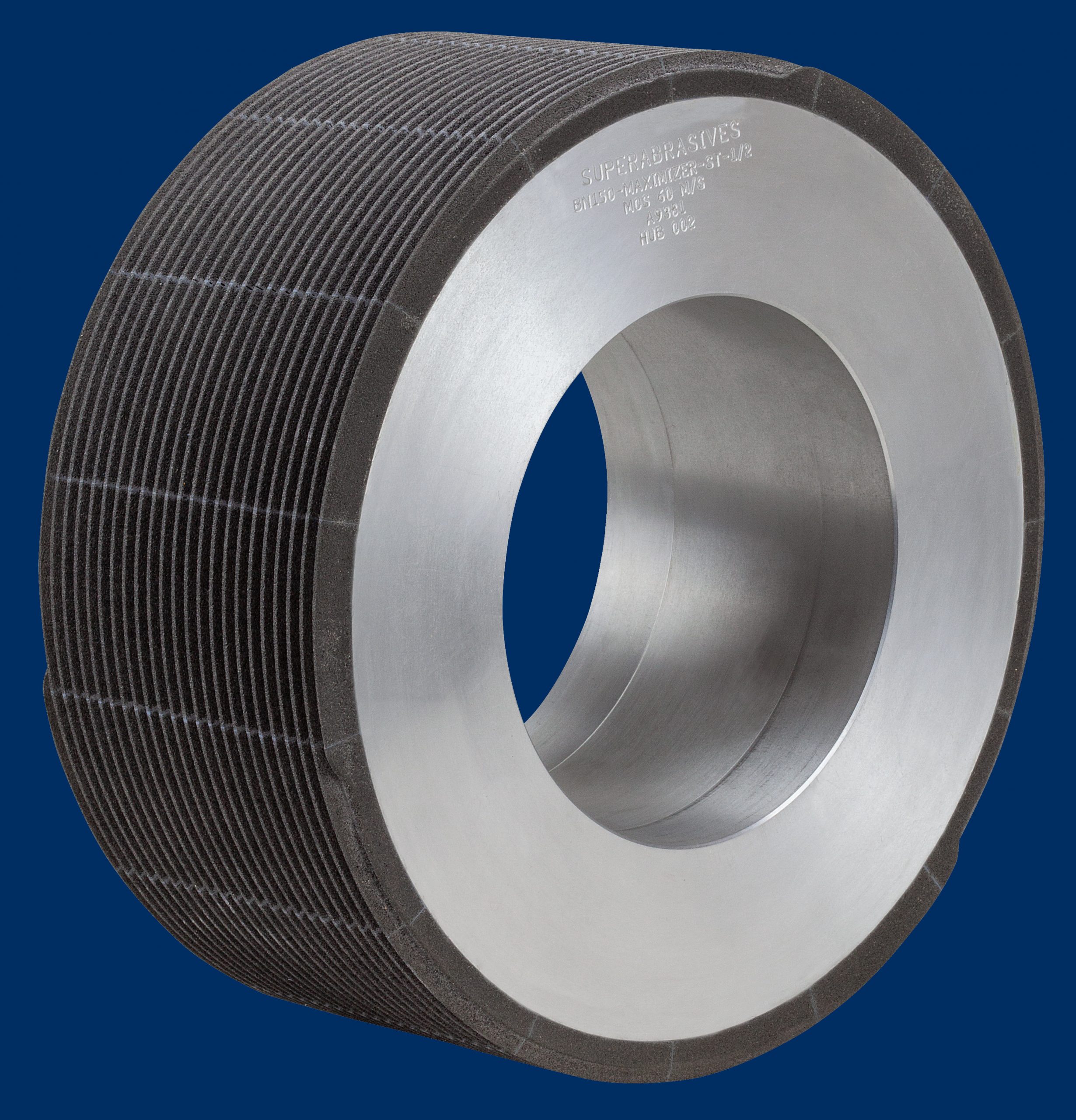

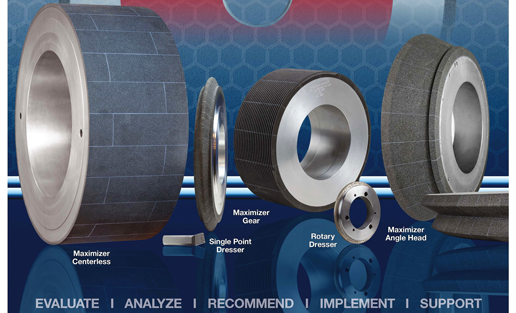

The MaximizerST can take deeper cuts with faster traverse rates with no wheel breakdown and reduced dressing. Both The Maximizer and MaximizerST products can produce the exact finish you require without the need for multiple wheels and operations for roughing and finishing. All that’s needed is adjustments to the dress traverse rate and exact finishes can be achieved using one wheel and one mesh size.

These products are so versatile that they can grind all types of materials and on all types of machines. Listed below are many options but just because it’s not listed here doesn’t mean we can’t do it – ask us for about your specific application.

- Horizontal Reciproc…

- Horizontal Rotating

- Vertical Reciprocating

- Vertical Rotating

- Hob Sharpening

- Manual NC & CNC Traverse & Plunge Thread

- Manual NC & CNC Through Feed Straight Plunge

Like our High concentration vitrified products, all Maximizer products can be made using our Engineered Segment System, which allows us the flexibility to manufacture many sizes and styles of wheels without imposing limitations. This unique manufacturing method is simple, but highly productive. We begin with a custom design of the abrasive section of the wheel utilizing individual segments, and then use a precision assembly process to create the finished product. This system provides us with the perfect tool to manufacture intricate forms based upon your exact requirements. And, with machine manufacturer’s requiring precision machined hubs and the cost of raw materials on the rise, the cost of purchasing new wheels every time is substantial. Our Engineered Segment System offers an effective solution and savings in both dollars and time, by re-using an existing wheel hub and mounting new abrasive segments to it. And should a mishap occur and the wheel is damaged, we can replace ONLY the damaged segments – not the entire wheel – keeping your costs and down time to a minimum. Overall, the savings are significant.

See the Standard Superabrasive Wheel Shapes under Resources but if you don’t see a shape that you’re looking for please contact us. Our engineers can work from sample wheels, wheel drawings or many of the most commonly used CAD program files to develop the form, so ask your sales representative, contact us directly at (248) 348-7670 or email us at sales@superabrasives.com.